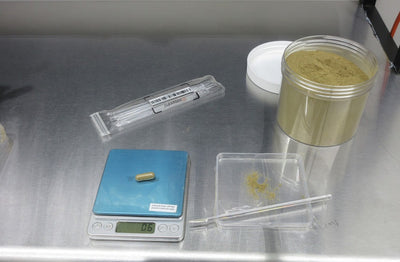

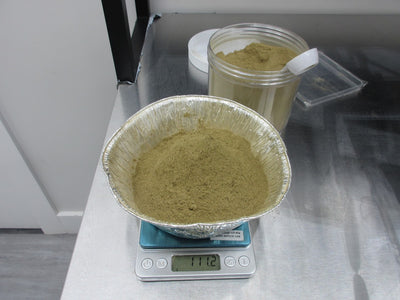

Measuring the Right Amount

Before starting, we test one capsule by filling and weighing it. This helps us calculate the correct powder amount for your order, since powder density can vary by batch.

Preparing the Empty Capsules

We place the empty capsules into an orientator tray, which aligns them with the body (bottom) facing down. Then, we separate the tops from the bodies so they’re ready for filling.

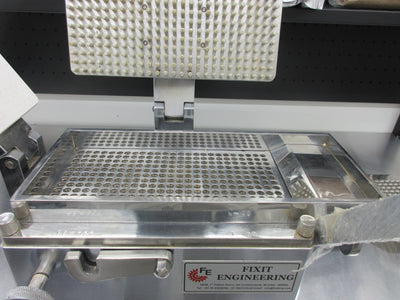

Setting Up for Filling

We place the tray of empty capsule bodies into the filling apparatus and remove the capsule tops for the next steps.

Loading the Capsule Bodies

The empty capsule bodies are lowered into the filling machine. The separated tops are set aside to be used later.

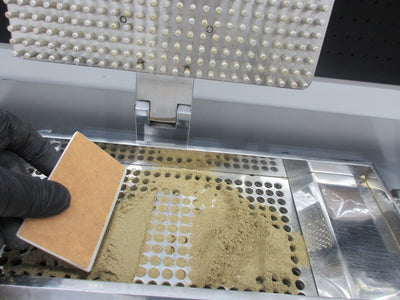

Attaching the Filling Frame

A filling frame is placed on top of the machine to help spread powder evenly into all capsules.

Calculating Powder for the Whole Batch

Based on the earlier test, we calculate the total amount of powder needed to fill your capsules.

Filling the Capsules

We spread the powder into the open capsule bodies using the filling frame.

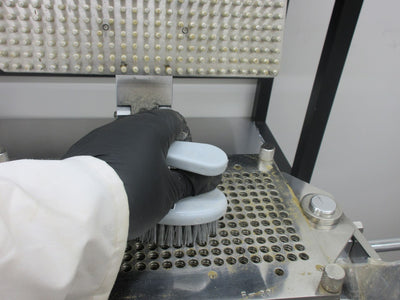

Tamping the Powder

We press (tamp) the powder down to make room, ensuring each capsule is filled to its full capacity.

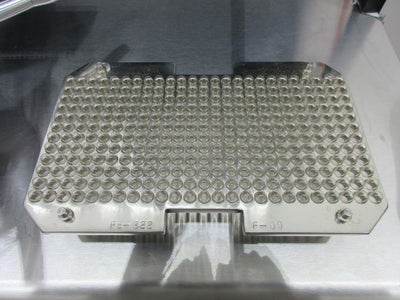

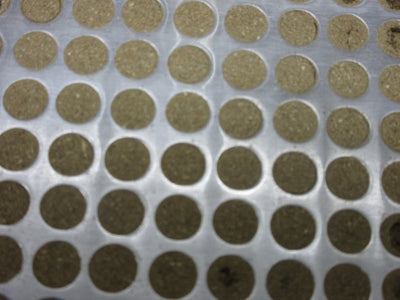

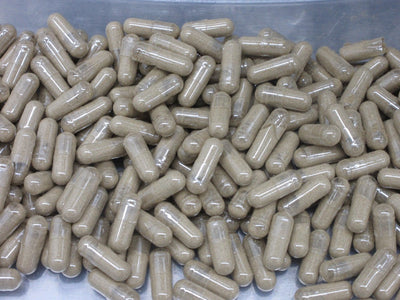

Capsules After Filling

The capsule bodies are now fully filled and ready to be sealed.

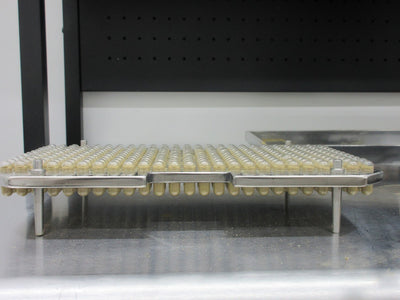

Locking the Capsules

We reattach and lock the tops onto the filled capsule bodies, creating complete capsules.

Inspecting the Capsules

Each capsule is checked to ensure it’s sealed, filled properly, and free of defects.

Counting the Capsules

We count the finished capsules to make sure your order is accurate.

Ready for Delivery

The completed capsules are packed in jars and prepared for shipment.

Cleaning Up

After each batch, we thoroughly clean the capsule filling tools to maintain hygiene and quality.